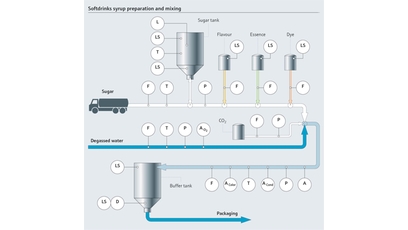

在饮料行业中,稳定产品质量是重中之重。在此前提下,产品安全、精准原料添加剂量、监测所有关键工艺参数、完整数据记录,以及成本意识都是重要的影响因素。创新的过程仪表帮助您应对上述挑战,涵盖从原料输送、添加、混合,及灌装的不同工艺过程。

关键点

1300 亿升

每年,全球软饮料的消耗量约为1300亿升。始终如一的品质与安全至关重要。 资料来源:www.historyofsoftdrinks.com

©Ueberkinger

©Ueberkinger

高精度含糖量测量

为了确保软饮料或果汁品质稳定,含糖量是一个非常重要的质量参数。基于密度测量值可以轻松计算出浓度值。选择在线测量技术,基于实时产品数据进行不间断产品质量监测, 有效缩短了手动取样时间和生产中断时间。

我们的行业专业知识

Endress+Hauser提供多种精准在线密度测量技术,满足软饮料生产的测量需求。

- 使用Proline Promass 科里奥利质量流量计(比如Promass Q)测定管道中流体的密度。

- 使用音叉密度计算仪FML621检测介质,计算参考密度,以及计算液体浓度,并将测量值转换为°Brix、°Baumé、°API等单位的数值。

©Rotkaeppchen-MUMM

©Rotkaeppchen-MUMM

投加添加剂

按照软饮料配方正确配料,必须精准的添加配料和添加剂。一方面,它直接影响产品质量;另一方面,它还能有效的利用高价值的原料。

我们的行业专业知识

由于添加剂的电导率低,需要使用高精度流量计测量,比如甜味剂、香精或色素。

- 使用Proline Promass F 100科里奥利质量流量计,具有高测量精度,且配备超紧凑一体型变送器。

©Ueberkinger

©Ueberkinger

可靠数据管理

全方位的数据记录是产品可溯源的基础, 对饮料生产过程实施有针对性的监测和优化。

我们的行业专业知识

Endress+Hauser数据管理器清晰记录、显示和保存过程测量值。通过电子签名限制访问权限,加密管理数据(符合FDA 21 CFR第11章要求)。

- 按需选择合适的数据管理器,灵活满足过程和应用要求。

©Endress+Hauser

©Endress+Hauser

高效相分离

管道内的产品状况清楚明了,再也无需置疑。相分离监测传感器精准识别出各种最终产物的相界面,区分排放废液和清洗液,或确定介质污染程度。

我们的行业专业知识

即使发生了最轻微的颜色变化,我们的光学传感器也能够实现精确的在线液体色度测量。您可以查看管道内的介质是产品的质量、清洗液或冲洗水。

- 使用OUSAF22光学传感器在可见光光谱范围内实现高精度的在线液体色度测量。

©Endress+Hauser

©Endress+Hauser

智能校准管理

食品与饮料行业对食品安全、产品质量和工艺可靠性有着严格的法律法规要求,因此必须定期校准仪表。测量仪表必须符合质量管理体系(例如ISO 9001,HACCP,IFS)的要求,这一点至关重要。

我们的行业专业知识

Endress+Hauser无缝可溯源仪表校准既可在现场操作,也可在我们的校准实验室中操作,保证产品质量长期稳定性,提高了装置的可用性,提升了工艺过程的成本效率。

- 详细了解我们的服务产品,确保您的关键工艺始终合规。

优势

我们竭力为您提供合适的解决方案,保证稳定的产品质量、较高的工艺过程和产品的安全性。我们的行业专家团队经验丰富,基于关键工艺参数,帮助您选择合适测量仪表,正确进行选型计算。我们重视可持续的客户关系,期待与您携手同行。

关键点

100%

产品安全完全得益于在线质量测量

关键点

30%

选择相分离光学测量技术,实现30%产品节约

关键点

>10%

超过10%的Endress+Hauser全球员工为您提供专业服务

我们为您提供的产品、服务和解决方案

Endress+Hauser了解严格的行业要求,清楚知晓软饮料制造商面临的严苛挑战。我们为用户提供型号齐全的卫生型仪表,包括流量、物位、温度、压力和液体分析等产品,并专门针对食品和饮料行业进行上述产品的设计、制造和优化。我们的共同目标是:始终如一地提升、保持和确保产品质量和消费者安全。

- 精准可靠的测量技术,专门针对饮料行业的专属要求进行优化。

- 传感器易清洗,全密封设计。最高防护等级可达IP69K,耐受高压和蒸汽清洗。

- 卫生型传感器,符合全球卫生标准,通过EHEDG测试。

- 与食品接触的部件材质符合FDA “GRAS”、EC 1935/2004和国标GB4806。

- 可与任何控制系统无缝集成。

浏览我们的产品系列

©Ueberkinger

©Ueberkinger

Accurate sugar concentration

The sugar concentration is an important parameter for the consistent quality of a soft drink or juice. The concentration can be easily calculated by measuring the density. Inline measurement technology enables permanent quality monitoring based on real-time product data. This reduces time-consuming manual sampling and production downtime.

Our expertise in the field

Endress+Hauser offers various technologies for precise inline density measurement in soft drink production.

- Determine fluid density in pipes using Proline Promass Coriolis flowmeters, such as Promass Q.

- Rely on our Vibronic Density Computer FML621 for medium detection, to calculate the reference density, to calculate the concentration of a liquid and to convert values to different units such as °Brix, °Baumé, °API etc..

©Rotkaeppchen-MUMM

©Rotkaeppchen-MUMM

Dosing of additives

The correct conversion of the soft drink recipe depends on the precise dosing of ingredients and additives. On the one hand, this has a direct influence on product quality and, on the other hand, it also guarantees efficient handling of cost-intensive raw materials.

Our expertise in the field

Due to their low conductivity, it is necessary to use highly accurate flowmeters to dose additives, such as sweeteners, flavors or colors.

- Use Proline Promass F 100, the flowmeter with premium accuracy and an ultra-compact transmitter.

©Ueberkinger

©Ueberkinger

Reliable data management

The key to product traceability lies in seamless data recording. It enables targeted monitoring and optimization of your beverage production process.

Our expertise in the field

Using data managers from Endress+Hauser, the recorded process values are clearly displayed and stored. The data are secured by personal access rights with electronic signatures (in accordance with FDA 21 CFR part 11 requirements).

- Select the right data manager from a large portfolio depending on your specific process requirements and application.

©Endress+Hauser

©Endress+Hauser

Efficient phase separation

No more guessing: From now on, you know exactly what's in your pipes. Sensors for phase separation enable exact detection of the phase transitions between end products, discharge and cleaning media or the degree of contamination in the respective medium.

Our expertise in the field

Our optical sensors for precise inline color measurement in liquids detect even the slightest color changes. You can see whether and in what quality the product, cleaning agent or rinsing water are in the pipe.

- Use OUSAF22, an optical sensor for precise inline color measurement in liquids in the visible region of the electromagnetic spectrum.

©Endress+Hauser

©Endress+Hauser

Smart calibration management

Strict requirements and regulations in the food and beverage industry with regard to safety, quality and reliability make regular calibration a must. The focus is on measuring instruments that are integrated into a quality management system (e.g. ISO 9001, HACCP, IFS).

Our expertise in the field

Endress+Hauser's seamlessly traceable calibration - either on your premises or in our calibration laboratories - ensures long-term product quality, increases plant availability and increases the cost efficiency of your processes.

- Learn more about our corresponding services and and keep all your critical processes in spec.

Our offering

Endress+Hauser understands the high demands and challenges faced by manufacturers of soft drinks. We offer a complete portfolio of hygienic flow, level, temperature, pressure and analytical sensors designed, manufactured and optimized for the food and beverage industry. Our common goal: increase, maintain and ensure product quality and consumer safety in the long term.

- Precise and reliable measurement technology optimized for the requirements of the beverage industry.

- Easy to clean and absolutely tight sensors. Ingress protection class up to IP69K available to withstand high pressure and steam cleaning.

- Hygienic sensors meet global sanitary standards and are certified according to EHEDG test procedure.

- Food contact material compliant to FDA "GRAS", EC 1935/2004 and China GB4806.

- Seamless integration into any control system.