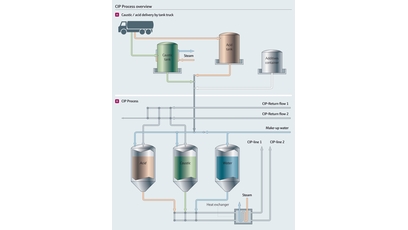

随着原材料和能源成本的不断上升,食品饮料厂的设备效率变得越来越重要。仍有许多食品工厂使用自动化程度较低的CIP原位清洗系统,完全依赖定时控制工艺过程和人工验证。安装在线传感器,实时监测和控制清洗过程,这有助于缩短清洗时间,降低能耗,节约资源;同时,还能实现完全可溯源。

关键点

30%

的清洁剂成本

Endress+Hauser 的电导率和光学测量确保准确的清洗液浓度测量和高效相分离,节省了 30% 的清洁剂成本。

©Monty Rakusen/Cultura Images RF/Strandperle

©Monty Rakusen/Cultura Images RF/Strandperle

精准的浓度测量

为了保证CIP清洗系统具有最佳性能,必须清楚知晓管路和CIP罐中清洗液的浓度。

我们的行业专业知识

电导率传感器的维护和校准需求极低,能够有效降低能源,化学品和水的使用量。Endress+Hauser提供多种CIP专用电导率传感器和变送器配置选择, 涵盖从入门级的紧凑仪表,到支持以太网通讯的多通道测量系统。

- 根据实际应用工况选择合适的电导率传感器和变送器,优化浓度测量。

©Juice Images/Strandperle

©Juice Images/Strandperle

高效的相分离监测

确切辨别管道中的产品,无需猜测。传感器用于判定CIP清洗过程中当前阶段的结束时间和下一个阶段起始时间。

我们的行业专业知识

可以联合使用电导率传感器、光学浊度传感器或pH电极,判定管线中是产品或冲洗水,在确认经水冲洗后管道中无产品残留后启动CIP系统。快速响应十分重要,它能够降低产品和水损耗,节约时间。

- 从Endress+Hauser液体分析产品中选择最合适的传感器,优化改进相分离监测。

©Endress+Hauser

©Endress+Hauser

可靠的液位测量

可靠监测CIP清洗液剩余量,确保稳定供给。

我们的行业专业知识

通常,使用超声波液位计、导波雷达液位计或雷达液位计监测清洗液库存液位。在CIP清洗液酸碱罐、清水罐和回收水罐中,一般安装静压液位计或电容液位计,取决于实际罐体大小和用户使用习惯。低限或高限液位报警功能和空管检测功能(泵空转保护)有效确保安全库存液位,通常选用音叉或电导式/电容式传感器。

- 在众多测量原理和不同产品系列中选择满足实际测量要求的最合适的液位计。

©Endress+Hauser

©Endress+Hauser

稳定的流量测量

流量测量是实现高效CIP清洗的基础。保证形成强的湍流,达到所需清洗效果。

我们的行业专业知识

Proline Promag H传感器的测量管能够测量高温腐蚀性介质,并能在扰动流产生的强于常规振动的工况下进行稳定测量。Endress+Hauser提供的用于CIP流量计可保持多年的测量性能。流量计不仅能够输出流量测量值,还能输出温度和电导率测量值。

- 电磁流量计优势明显,不仅能够输出流量测量值,还能输出温度和电导率测量值。

©Endress+Hauser

©Endress+Hauser

可节能降耗的温度测量

可以在不同位置测量CIP清洗过程的温度,温度必须要密切监控,从而在清洗效率和能耗间找到合适的平衡点。通常,将其视为关键控制点,需要频繁进行温度校准检查。

我们的行业专业知识

iTHERM QuickNeck是我们的专利温度计延长颈,可实现仪表轻松快速在线校准操作。仅需简单旋转即可打开,执行校准操作后仪表重新安装,简便易行。

- 选择我们的温度传感器iTHERM TM411(采用QuickNeck技术),有效预防故障,节省时间。

©Endress+Hauser

©Endress+Hauser

识别黏附,保证清洗效率

清洗效率与温度、清洗液浓度、以及清洗液流经安装设备/管道内壁的流速和剪力大小相关。通常,管道并不是完全平直的,清洗喷球的冲洗状况也不一定理想,这就导致部分区域很难彻底清洗干净。为了测定并提高整体清洗效率,必须同时监测上述位置的清洗状况。

我们的行业专业知识

我们的紧凑型多参数测量仪表Liquitrend QMW43能够同时测量黏附层厚度和介质的电导率。仪表安装在食品加工厂中的关键工艺点,可靠监测流体状况,监控清洗后是否存在残留黏附。这一创新技术为工厂优化清洗频率和清洗强度提供了数据支持,可有效提升清洗效率。

优势

我们的员工与客户并肩努力,显著优化提升了CIP清洗工艺的效率。我们拥有丰富的行业知识和应用经验,完备的产品组合,助力您的成功。Endress+Hauser致力于成为您的可靠的全方位合作伙伴。

关键点

25-30%

每次CIP清洗均能够节约25-30%时间。

关键点

30%

采用光学仪表进行相分离监测,可使化学药剂使用量降低30%。

关键点

>100

我们的应用经验和行业知识已成功为100多个国家的用户服务。

我们为您提供的产品、服务和解决方案

我们熟知您在严苛的CIP工艺应用中所面临的挑战,可为您提供完整的卫生型仪表测量解决方案。我们为用户提供可靠的流量、物位、压力、温度和分析仪表,均遵循最严格的质量制造标准,满足食品与饮料行业的法规要求。我们能够为您提供:

- 坚固耐用,测量可靠,行业优化的卫生型传感器设计

- 测量传感器易清洗,全密封设计

- 创新的自诊断功能,确保测量结果始终可靠

- 无缝集成至所有控制系统中

浏览我们的产品系列

©Monty Rakusen/Cultura Images RF/Strandperle

©Monty Rakusen/Cultura Images RF/Strandperle

Accurate concentration measurement

To ensure optimal performance of a CIP system, it is critical to know the detergent concentration both in the loop and the make-up tank.

Our expertise in the field

Conductivity has the lowest maintenance and calibration requirements and enables you to reduce energy, chemical, and water usage. Endress+Hauser offers multiple conductivity sensor and transmitter options specifically designed for CIP applications. From compact entry-level to multi-channel systems with Ethernet integration capabilities.

- Optimize concentration measurement with the right conductivity sensor or transmitter for your application.

©Juice Images/Strandperle

©Juice Images/Strandperle

Efficient phase separation

Know exactly what is in the line and remove the guesswork. Transition sensors determine when each phase of the CIP cycle ends and the next should begin.

Our expertise in the field

Conductivity, optical turbidity or pH sensors are used to determine when product or rinse water is in the line, starting the CIP system only if zero product remains after rinsing. Fast response is very important to reduce product and water loss and save time.

- Improve your phase separation by choosing the best fit sensor from Endress+Hauser’s liquid analysis portfolio.

©Endress+Hauser

©Endress+Hauser

Reliable level measurement

Inventory of CIP detergents need to be monitored to ensure stable supply.

Our expertise in the field

Ultrasonic, guided or free-space radar are common methods for inventory monitoring of cleaning agents. Make-up, rinse and recovery tanks are commonly monitored with hydrostatic or capacitive sensors; selection is based on tank size and personal preference. Inventory safety is ensured by low/high level alarms and empty pipe detection (pump protection) and are usually done with tuning fork or conductive/capacitive sensors.

- Identify the best-fit level instrumentation for your application from a broad range of measuring principles and the associated portfolio of products.

©Endress+Hauser

©Endress+Hauser

Robust flow measurement

Flow measurement is fundamental for an efficient CIP system. By ensuring a strong and turbulent flow, the desired scrubbing effect is reached.

Our expertise in the field

The Proline Promag H line is designed to handle the aggressive chemicals at elevated temperatures and higher than normal vibration due to turbulent flow. Endress+Hauser ensure performance for many years in CIP service. The flowmeters also include a temperature and conductivity output in addition to the flow value.

- Benefit from electromagnetic flowmeters which include a temperature and conductivity output in addition to the flow value.

©Endress+Hauser

©Endress+Hauser

Cost saving temperature measurement

Temperature within the CIP process can be measured at several locations and is closely controlled to ensure balance of the effectiveness of the cleaning and energy consumption. Often seen as a critical control point, temperature needs frequent calibration.

Our expertise in the field

iTHERM QuickNeck - our patented thermometer extension neck with quick release for fast and easy recalibration. One simple turning movement for opening and easy re-installation after calibration.

- Benefit from fault prevention and time savings using our temperature sensor iTHERM TM411 with QuickNeck technology.

©Endress+Hauser

©Endress+Hauser

Build-up recognition to ensure cleaning efficiency

Cleaning efficiency is based on temperature, detergent concentration and flow velocity/shear forces at the installation walls. But as the pipes are not always straight and the reach of the spray balls is not always ideal, there are spots which are difficult to clean. To determine and improve the overall cleaning efficiency, it is necessary to also monitor the cleaning behaviour at these spots.

Our expertise in the field

Our compact multiparameter device Liquitrend QMW43 can simultaneously measure the adhesion thickness and conductivity of media. Installed at critical points in the food processing plant, it reliably monitors fluid behavior and informs whether residual buildup is present after cleaning. This innovative technology allows the cleaning frequency and intensity to be tailored to the needs of a plant, thus increasing efficiency.

Our offering

We understand your challenges in demanding CIP processes and provide you with a full line of hygienic, sanitary measurement solutions. Our proven portfolio of flow, level, pressure, temperature and analytical instrumentation is manufactured to the highest quality standards and meets all food and beverage requirements and regulations. We offer you:

- Robust, reliable and industry-optimized sensors in hygienic design

- Easy to clean and absolutely tight measuring sensors

- Innovative self-diagnostics to ensure full confidence in measurements

- Seamless integration into any control system